Company

News

New developments in progress

2021 was a year of considerable development, with investments continuing into the current year.

2021-06 New turning department of 2,450 m2, with relocation of all Cnc lathes and installation of new high-tech equipment, e.g. Murata MW40 lathe for machining hardened gears for hole and face finishing, complete with Marposs Nemo station, for 100% inspection and correction of workpieces, machining with 9µ range, measurement oscillation within ±2µ.

2021-09 New Studer S31 Cnc grinding machine with 3 spindles and continuous B-axis, for tooling and production of high precision ground parts, in preparation automatic loading system with Fanuc robot.

2021- 12 New grinding department, with the addition of the third Reishauer, all with robot-controlled gear loading, in addition to which there are the Studer S31 and 2 Schneeberger.

2022-01 Insertion of 3 Megamat warehouses by Kardex, one per department, to store tools and equipment, with automatic system of drawer presentation according to the drawing code to be machined.

2022-03 New quality control department with the construction of 3 air-conditioned departments covering a total of 115 m2, where all the inspection machines are installed, both for gears (4 evolution gauges) and 3D cnc, optical and roughness measuring machines. The location is central to the production departments in order to rationalise inspection operations.

2022-04 New washing machine with modified alcohol brand IFP, with automatic loading/unloading system with 2 baskets.

2022-05 New photovoltaic system 201 kW is under construction, for a total of 445 kW, energy all self-consumed.

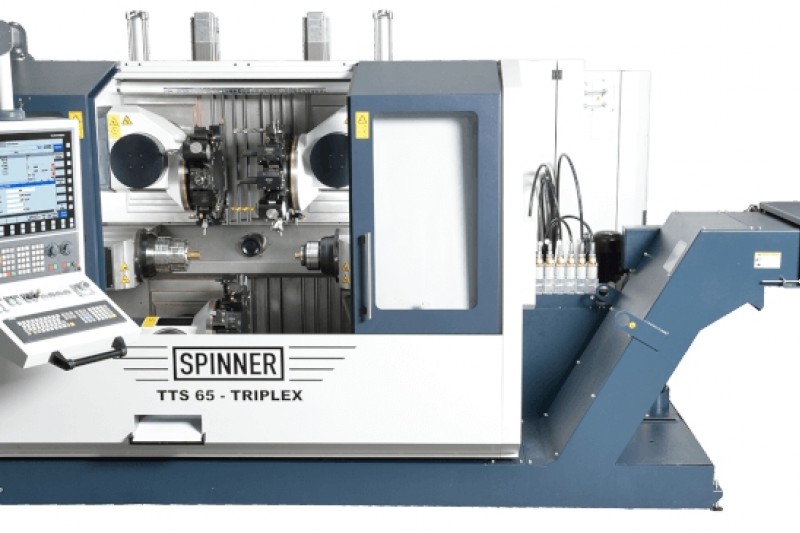

2022-05 New Spinner TTS65 Triplex CNC lathe, a machine with 2 electrospindles and 3 motorized tool-holder turrets, complete with automatic bar loader.

Voci Correlate

Scopri e leggi le altre voci